Post-Harvest Perfection: Cleaning, Drying & Grading Morels

Morel mushrooms (Morchella spp.) are among the most coveted wild fungi in the world, known for their distinctive honeycomb caps, complex umami flavor, and rare nutritional richness. From haute cuisine in Paris to functional wellness formulations in Berlin, dried morels are increasingly recognized not only as gourmet ingredients but as valuable bioactive resources.

But what transforms a freshly foraged morel into a high-value commercial product? The answer lies in a meticulous post-harvest process designed to preserve quality, protect potency, and ensure consistency.

This article explores the full post-harvest lifecycle of morel mushrooms—cleaning, drying, and grading—focusing on best practices that uphold the excellence expected in international trade, culinary arts, and nutraceutical innovation

The Importance of Post-Harvest Handling

Morels are fragile, moisture-rich mushrooms with a porous structure that makes them highly perishable. If not handled properly, they can quickly lose flavor, degrade nutritionally, or become vulnerable to mold and decay. For commercial stakeholders, post-harvest processing isn’t just routine—it’s essential to maintain product value, regulatory compliance, and consumer trust.

1. Cleaning: The Gateway to Purity and Safety

Fresh morels are harvested from forest floors—nestled among pine needles, leaf litter, soil, and sometimes insects. As such, they arrive coated with natural debris, which must be delicately removed without damaging the mushroom’s fragile walls.

Cleaning Objectives:

- Eliminate physical impurities (dirt, sand, leaves)

- Remove insects or larvae

- Avoid structural damage or excessive moisture

Common Cleaning Techniques:

- Dry Brushing: The preferred method for high-end culinary morels. A soft brush gently removes visible debris without introducing moisture.

- Air Blowing / Vibration Trays: Used to dislodge dirt and particles through mechanical means while minimizing human contact.

- Minimal Moisture Rinse (Selective Use): Employed only when debris is embedded. Mushrooms are briefly rinsed and promptly air-dried to prevent absorption.

Note: Immersing morels in water for extended periods compromises texture, shelf life, and flavor. Controlled cleaning is a balance between sanitation and preservation.

2. Drying: Where Longevity Meets Flavor Retention

Drying is the most critical step in transforming fresh morels into shelf-stable products suitable for global distribution. Proper drying ensures:

- Flavor concentration

- Microbial safety

- Color and texture retention

- Ease of transport and storage

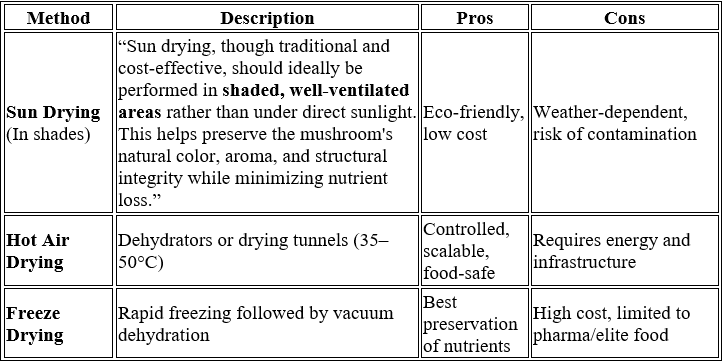

Drying Techniques:

Method | Description | Pros | Cons |

Sun Drying (In shades) | “Sun drying, though traditional and cost-effective, should ideally be performed in shaded, well-ventilated areas rather than under direct sunlight. This helps preserve the mushroom’s natural color, aroma, and structural integrity while minimizing nutrient loss.” | Eco-friendly, low-cost | Weather-dependent, risk of contamination |

Hot Air Drying | Dehydrators or drying tunnels (35–50°C) | Controlled, scalable, food-safe | Requires energy and infrastructure |

Freeze Drying | Rapid freezing followed by vacuum dehydration | Best preservation of nutrients | High cost, limited to pharma/elite food |

Drying Benchmarks:

- Target Moisture Content: 8–10%

- Ideal Drying Time: 8–24 hours (varies by method and size)

- Storage Conditions Post-Drying: Airtight, low-humidity, pest-proof environments

3. Grading: Sorting Value from Volume

Grading adds structure to the morel supply chain. It helps traders, chefs, extractors, and manufacturers select the right mushroom for the right application—whether for plating or powdering.

Grading Parameters:

- Size Classification:

- Mini (2–3 cm): Used in sauces, garnishing, and powdering.

- Medium (2–5 cm): Versatile, fits most culinary applications.

- Large/Jumbo (5+ cm): Premium grade for fine dining.

- Shape & Whole Structure:

- Whole mushrooms fetch higher prices.

- Broken or chipped morels are sorted for powder or extract-grade uses.

- Coloration:

- Dark brown to black morels are often most prized in many global markets, particularly in South Asia and the Middle East, due to their richer flavor, aromatic depth, and traditional culinary applications.

- Light golden-brown morels are preferred in some European fine-dining markets for their visual appeal and delicate texture after rehydration.

- Color variations may also reflect differences in habitat, drying techniques, and maturity. All grades have commercial value depending on the intended use—whether for plating, powdering, or extraction.

- Cleanliness Level:

- Extra-cleaned morels command a premium.

- Industrial or pharmaceutical grades may tolerate higher debris thresholds if processed further.

- Moisture Uniformity:

- Any variation risks spoilage.

Grading includes checking for “spongy” or “soft” pieces that signal incomplete drying.

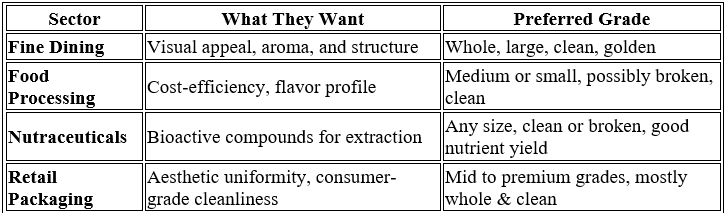

Why It Matters Across Industries

Sector | What They Want | Preferred Grade |

Fine Dining | Visual appeal, aroma, and structure | Whole, large, clean, golden |

Food Processing | Cost-efficiency, flavor profile | Medium or small, possibly broken, clean |

Nutraceuticals | Bioactive compounds for extraction | Any size, clean or broken, good nutrient yield |

Retail Packaging | Aesthetic uniformity, consumer-grade cleanliness | Mid to premium grades, mostly whole & clean |

From lab extractors to luxury kitchens, the right grade defines the value chain.

Conclusion: Excellence Begins with Care

Morel mushrooms are a rare gift of nature—but their commercial excellence is man-made. Every dried morel that reaches a plate or a product line has passed through an exacting series of post-harvest steps, each designed to honor the mushroom’s integrity and enhance its market potential.

By mastering the art of cleaning, drying, and grading, producers and traders unlock the full spectrum of morel value—from the culinary elegance of whole dried caps to the concentrated potency of extract powders.

FungiMatrix is proud to support global industries with premium wild-foraged morels sourced from pristine environments.

Want to learn more about sourcing or using dried morels? Visit www.fungimatrix.com